Custom strap loaf bread pans are essential for refining your baking process. By tailoring the shape, size, and material to suit your specific needs, custom loaf bread pans can enhance both baking consistency and production efficiency, ultimately elevating the quality of your final product. In this guide by Xinhua Bakeware loaf pans supplier in China, we’ll explore the importance of custom pans, provide insights on selecting the optimal options, and offer recommendations on where to source them. The key is finding the perfect fit for your bakery’s unique requirements.

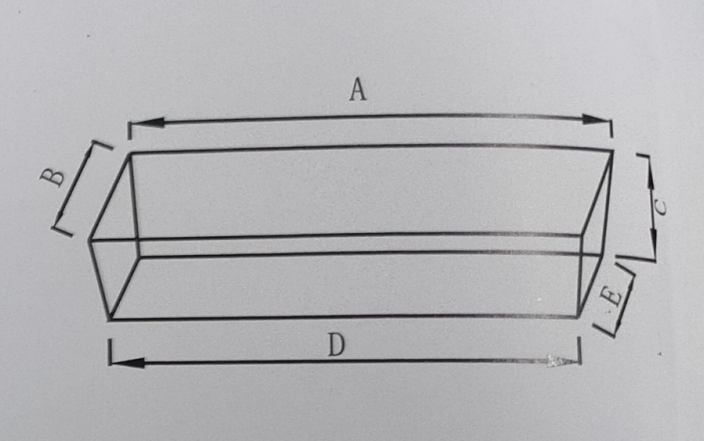

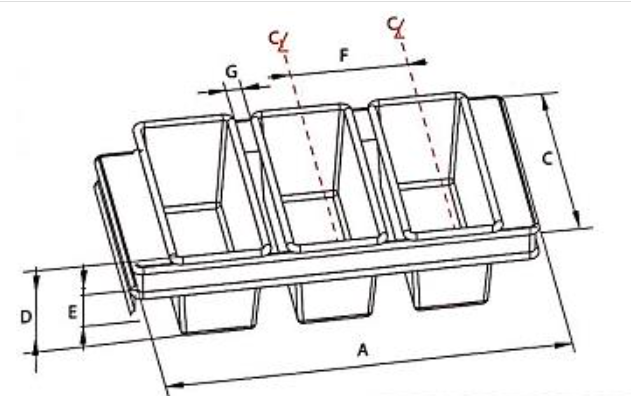

Only a few specifications we could manufactureyour customized product:

| A. Overal Length |

| B.Overal Width |

| C. Depth |

D Frame Height |

| E.Bottomin Diameter |

| E Center-to-center |

| F.Center-to-center distance |

| A. Overal Length |

| C.Overal Width |

| D.Depth |

| E.Frame Height |

| F.Center to Center |

| G.Individual Distance |

Others:Material Requirement ,With/Without Lid Individual tin design ,With/Without Handle ,With/Without Vent Holes, With/Without Coating ,Corrugated Wall or Plain |

How to choose the right custom bread pans for your bakery?

Choosing the right custom bread pan is a crucial decision for any bakery. It's not just about size and shape; the loaf pans should also meet your specific baking goals. Here are the key factors to consider:

When choosing a bespoke loaf pan, the focus should be on size, materials and the production requirements of the bakery. Baking trays should be designed to optimise heat distribution and ensure even baking, while also accommodating the uniqueness of the bread you produce. Customising baking trays to your specific baking process will help maximise efficiency and product quality.

Custom strap loaf pans are not a one-size-fits-all solution. Every bakery has distinct requirements based on the types of bread they produce, their production scale, and their efficiency goals. Whether you're crafting artisanal loaves or mass-producing sandwich bread, selecting the right pan is essential. Here’s how to approach it:

Size & Shape: Consider the loaf sizes and shapes your bakery produces most frequently. Whether you're using strap loaf pans for large batches or specialized shapes like cylinder shape or heart shaped, your pans should be designed to meet these specific needs.

Material: The material of your pans plays a significant role in heat conduction and durability. For example, aluminum metal baking pans provide excellent heat distribution, while aluminized steel baking pans are favored for its unique blend of strength and heat retention, making it an ideal choice for commercial use in high-performance baking.

Customization: Custom designs can offer significant advantages, particularly for high-volume production like machinery production system. Precision-engineered pans can improve consistency, streamline your processes, and help maintain the quality of your loaf bread, even in large-scale operations.

Baking Efficiency at Scale

In large-scale bakeries, efficiency is paramount. Custom strap loaf pans are specifically designed to enable simultaneous baking of multiple loaves, optimizing oven space and reducing overall baking times. This not only increases production throughput but also ensures that every loaf maintains consistent texture, shape, and quality—essential for maintaining strict quality control in mass production.

Additionally, custom strap loaf pans can be tailored to seamlessly integrate with your existing production lines, enhancing workflow efficiency. By maximizing space utilization and accelerating production cycles, these pans empower you to meet growing demand without sacrificing the quality your customers expect.